Nanotech Gravitas™ Technology

- Escalating bulk water chemical costs

- Water treatment chemicals logistics to remote locations

- Chemical inventory management and handling

- Maintenance of process equipment and chemical dosing equipment

- Seasonal raw water feed quality variations

- Inconsistent production quality and quantity

- Process efficiency variation of clarifiers and sand filters

- Water losses from sludge removal and sand filter back washes (10 % – 20 %)

- Rising Energy cost in R/m3

- Huge footprint and space required for existing and future operations

- Capital intensive and long lead times

- Civil construction takes months if not years to complete

- Access to capital expensive and scarce

Implications from non-compliance

- Inconsistent quality of treated water

- Unsafe water for human consumption

- Communities up in arms at times of short supply and no delivery

- Cannot bill the end user for water consumed

- Compliance Issues relating to micro counts

- Frustration and aggression from communities

- Consumers don’t trust you despite all efforts

- Political sensitive issue as always

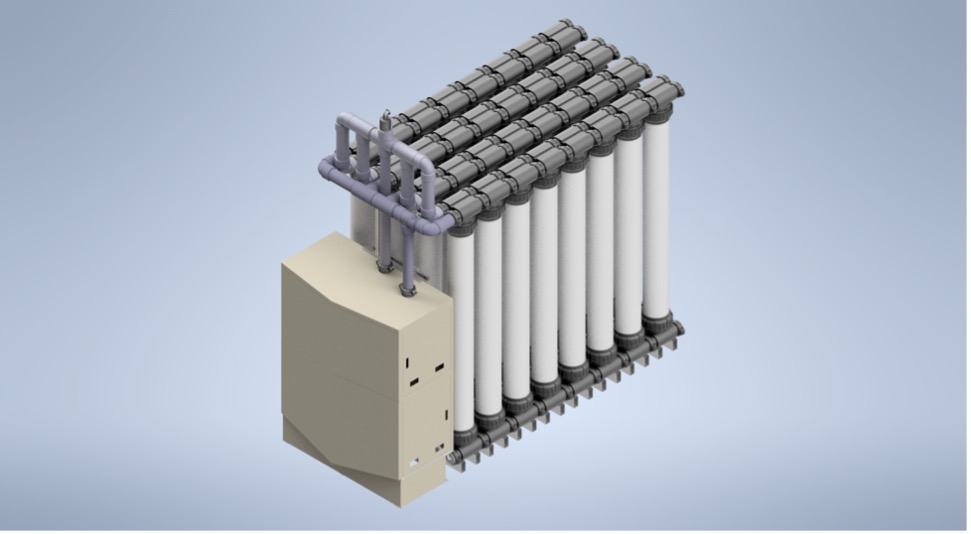

Nanotech offers a new technology: Gravitas™

The ultimate checklist for a perfect water treatment plant

- Absolute Barrier

- Constant High Quality outlet

- Low Energy Use

- Use of Gravity to feed membrane system

- No carry over of solids

- No Toxic Zone

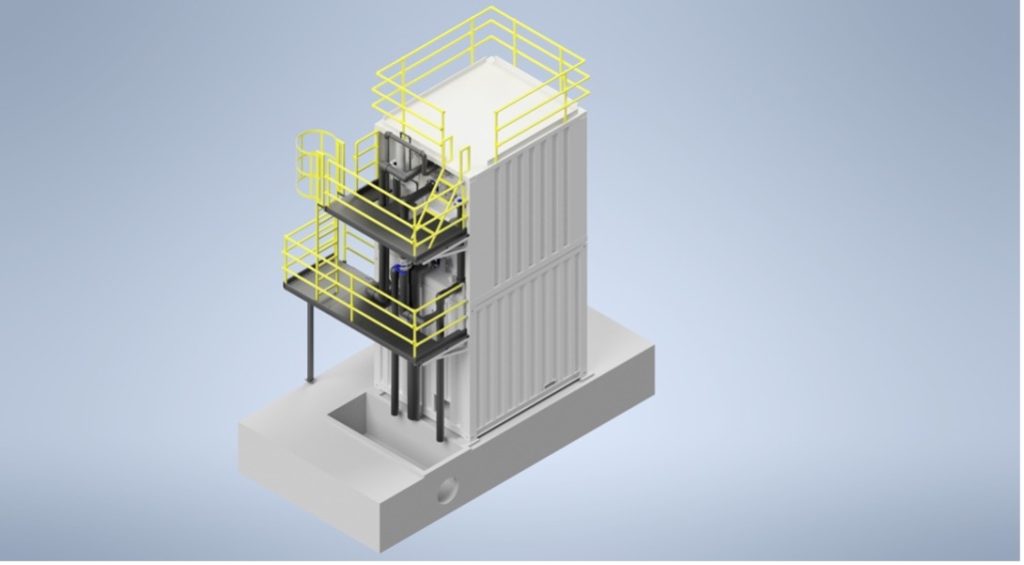

- Modular in construction

- Solar power option possible

- NO BULK WATER TREATMENT CHEMICALS

Typical results from Gravitas Water Treatment Plant

- Clarity in NTU less than 0.1

- Footprint is 15 % of a conventional plant for the same flow

- You can achieve 4 times the flow for the same space occupied.

- Water recovery is 97 %

- Electrical power consumption of 0.017 kWh/m3

- Installation time is in days and not months

- Flux is 230 m3/d/m2 vs that of conventional flux of 55 m3/d/m2

- 4 times more flow for the same area

Nanotech Gravitas™ Process: The Future of Water Treatment Plants

Operations Excellence and Compliance:

Future of Efficient Water Treatment Plants

Switching to advanced membrane-based water treatment systems is a significant move. This step helps ensure that clean water is available to everyone in the future. This is a huge step towards improving access to clean water for all.

Advanced membrane-based systems play a crucial role in making clean water accessible to everyone. Nanotech’s Gravitas process demonstrates the potential impact of using new ideas to benefit the environment and society.

In summary, the benefits of adopting Nanotech’s new technology approach in water treatment plants are clear and compelling:

- An absolute barrier to contaminants, ensuring constant water quality.

- Dramatically reduced energy requirements in the use of gravity.

- A modular, quick-to-deploy construction that’s both time and cost-effective.

- The potential for solar power supply, enhancing the system’s efficiencies.

- No use of bulk water treatment chemicals, favouring a safer, more environmentally friendly process.

Contact us and get COMPLIANT!

Contact us for the top technology in chlorine dioxide to ensure compliance throughout your operations.

What to do next?

Call our team if you have any questions. We’re happy to help in any way we can.