Nanotech LiquiChlor™ Technology

The Nanotech systems are in line with global corporate expectations of reliability, efficiency, quality and safety. The slogan “Disinfect and Defend” is a proven strategy in chlorine dioxide water treatment applications.

We have served the market since 2007 and have developed the ultimate water disinfection technology offer.

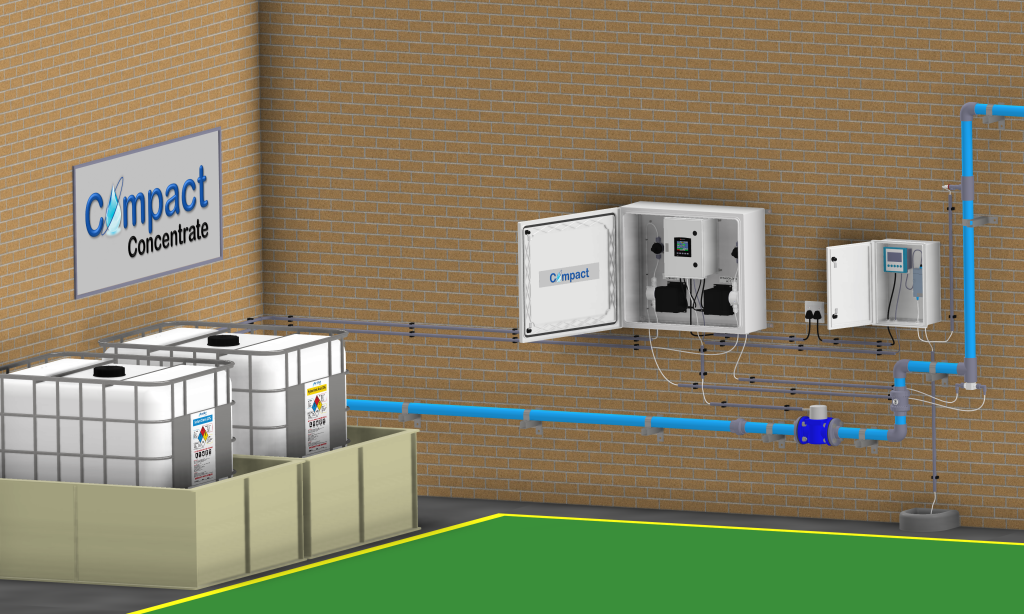

Chlorine dioxide (ClO2) from Nanotech is available in:

- Powder formulation for very small applications

- RTU liquid for small applications.

- 2 chemicals precursors

- 3 chemicals precursors

- Chlorine gas technology

- Electrolytic generation

- Ion Exchange technology

We have built a list of FAQ below on the most asked questions for your convenience:

Why Chlorine Dioxide?

Chlorine dioxide (ClO2) disinfects by oxidation, and NOT by chlorination. The efficiency of killing power is easy to control within an ORP range. The alternative control measurement is measuring the residual ppm of ClO2 in the water.

Chlorine dioxide is a highly selective oxidant because of its unique electron transfer ability. Chlorine dioxide gas dissolved in water is 10 times more than chlorine gas.

It does not hydrolyse but stays in solution as a gas until consumed or removed. Chlorine dioxide in comparison to chlorine gas does not form THM (Trihalomethanes) and other DBP’s in the process.

Who can use Chlorine Dioxide?

Industry use disinfection and purification technologies for most water treatment applications. These applications are typically the following:

- Municipal water treatment, pre-oxidation and post disinfection

- Mining industry for process water disinfection

- Food and beverage industry for process water disinfection

- Oxidation of manganese and iron in borehole water sources

- Wastewater disinfection

- Abattoirs wastewater and process water disinfection

- Poultry feed water disinfection

- Any other industrial or commercial water treatment application for disinfection

What are the Advantages?

- More effective than chlorine for the killing of viruses, Cryptosporidium and Giardia.

- It oxidizes iron, manganese and sulphides quickly.

- CLO2 does not react with ammonia gas in a process.

- Enhances the coagulation process, affecting the zeta potential of particles.

- TOC reduction of up to 58 %, prior dosing to coagulation process.

- Taste and odour removal, no use of powder-activated carbon.

- It has a 6 times higher oxidizing power than chlorine, so you can dose less.

- CLO2 does not hydrolyse and is effective over a pH range of 4-10.

- Easy to measure free residual with standard equipment.

- Capital cost significantly lower than that of a chlorine installations.

- Barriers of entry much lower because no legislation like that of chlorine.

- Chlorine dioxide is a registered EPA chemical. (Registration 74986-1)

- SANS 52671:2007 approval – intended for Human consumption.

Why does Chlorine Dioxide work better than my Chlorine or Bromine?

Chlorine dioxide penetrates biofilm and kills it from the inside. On the other hand, chlorine “burns” biofilm from the outside, depleting it and making it inferior.

The chlorine dioxide penetrates the biofilm, kills it, then remove it from the attached surface. Second, the chlorite formed from the chlorine dioxide acts as a bacteriostat and retards bacterial and micro growth.

Which generation technology is best?

The mixing of powder products, 2 or 3 precursors, or chlorine gas systems can all produce ClO2.

A few variables affects the choice:.

- Remote locations, distance from power zone

- Level of automation required

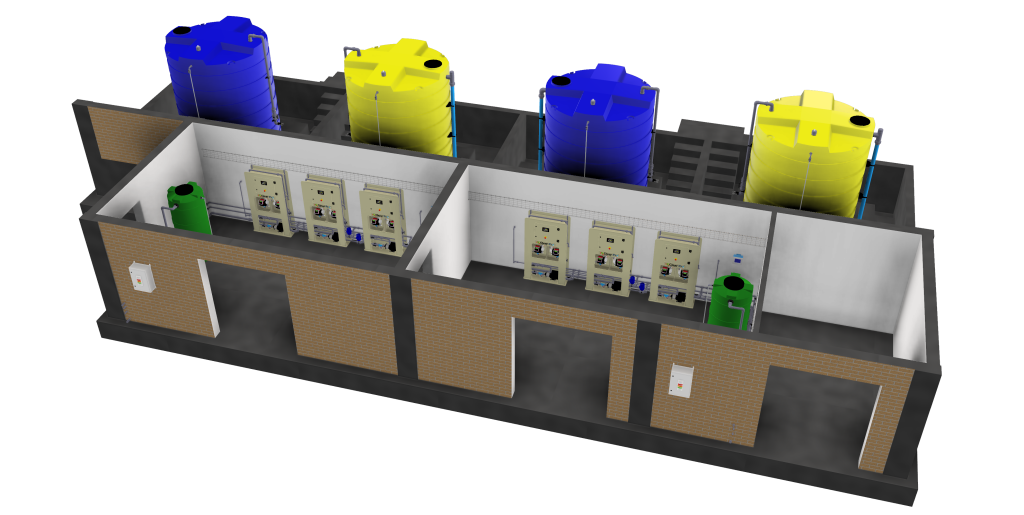

- Capacity of systems

- Volumes of water to be treated

- Operator skills available

- Skilled maintenance crews

- Complexity of operation

Nanotech will advise based on years of experience and the combination of above variables the best option to install.

Why get the technology from Nanotech?

We have designed and installed every chlorine dioxide generation technologies for years. The technology started with the oxidation of sodium chlorite, followed by the reduction of sodium chlorate.

Finally we moved over the complex chemistry of using chlorine gas to manufacture chlorine dioxide for water treatment applications.

Each industry has its own expectation and benefit of the value chlorine dioxide offers. Nanotech took all the lessons learned over the years and designed our systems to cater for these demanding requirements.

What is the life expectancy of the generators?

Nanotech chlorine dioxide systems will last for the lifetime of the supplier’s component guarantees. We extend our guarantees with SLA’s to keep systems running long after the due date.

How much Chlorine Dioxide to use in my process?

A demand study determines exactly what the process needs to achieve compliance. This study is compulsory for the correct sizing of systems. Nanotech determines this demand on site over a period to compensate for seasonal or process fluctuations.

What maintenance do the Chlorine Dioxide generators require?

Nanotech schedules monthly and quarterly maintenance sessions to ensure availability of the system and its components.

How do I control Chlorine Dioxide dosage in my process, when is it too much or too little?

Water treatment plants measure and control the chlorine dioxide residuals to the required setpoint. We use ORP or free chlorine dioxide levels. Systems maintain residual chlorine dioxide levels in the range of 0.2 ppm to 0.4 ppm. The typical ORP values range between 750 to 780 millivolts.

Guarantees

When you install one of our systems, we offer a SLA agreement to maintain this system. We also supply the chemical precursors and monitor performance, ensuring optimum performance of the system.

We guarantee the process and outcome long after you have taken ownership of the equipment. All components are locally available, and we keep the critical spares in stock.

Based on the above questions and answers:

The chlorine dioxide generators operate in under-water conditions for absolute safety. The underwater reactors are a proudly South African development and patent pending.

Now the responsibility is YOURS!, Contact us now to get micro compliant in record time.

Our project managers are responsible for the technology from trial to full implementation and manage the maintenance long after handover. Our clients deserve good service and support in this high-tech environment. So, call us and we will get your project seamlessly implemented and give you the peace of mind you deserve.

In choosing Nanotech as your technology partner, you made the RIGHT, but INFORMED AND EDUCATED CHOICE!

Contact us and get COMPLIANT!

Contact us for the top technology in chlorine dioxide to ensure compliance throughout your operations.

What to do next?

Call our team if you have any questions. We’re happy to help in any way we can.