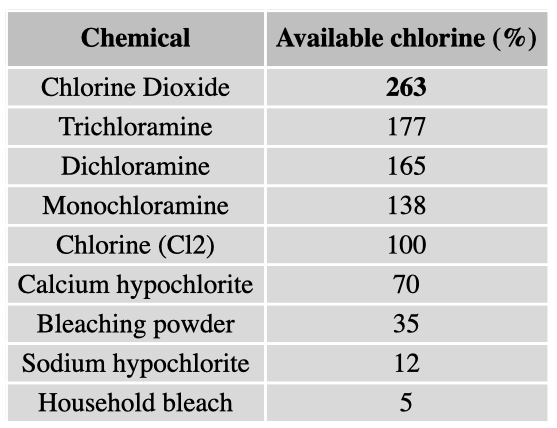

Nanotech has reinvented chlorine dioxide as the preferred killing agent and mechanism, outperforming its fellow competitors by multiple log reductions, both safely and effectively. Chlorine Dioxide – The Nanotech way! Your ultimate solution to the invisible world of microbiological challenges has arrived.

Nanotech has re-engineered chlorine dioxide generation methods to adapt to changing customer requirements and sensitivity to dangerous byproducts and contaminants. Nanotech designed chlorine dioxide generators to produce PURE ClO2 gas dissolved in water with stoichiometric efficiencies.

Question – How do you choose between the vast array of chlorine dioxide technologies available on the market? You could choose from two-powder formulation, RTU or ready-to- use liquid, 2 chemicals, 3 chemicals, chlorine gas technology, chlorite or chlorate chemistries. How do you know which one is best for you?

So, what do you do?

Nanotech has been involved in chlorine dioxide generation for years. They build their systems locally, testing all the chemistries known by using sodium chlorite and sodium chlorate. Each one of these technologies has its own unique advantages and disadvantages. Nanotech learns from all the existing advanced systems and develops them into superior systems fit for the African market. These systems are now in line with global corporate expectations of reliability, efficiency, quality and safety.

Nanotech has paid all the school fees over the years to develop the “perfect” system and made all the mistakes. This means our clients don’t have to go through this pain. They don’t have to investigate all the options from every supplier. Nanotech has asked all the right questions. If you don’t ask the right questions, you will not be told the implications of your choice. As the old saying goes “buyer beware”, if you don’t get it right then your decisions may come back to bite you.

So, to answer the question “what do you do?” I would recommend giving Nanotech the challenge to solve any process issue where chlorine dioxide is required. Put us to the test against any other local supplier and experience the difference! The promise we make to our clients is the guarantee of locally engineered technology, backed with competent and skilled engineers. There are no commission-based salespeople to talk to. For us it is about our slogan.

We have served the market over the last 15 years and have developed the slogan below. In our opinion, this will be the only factor of success in our current economic climate.

FAQ – Frequently asked questions (which you should ask!)

1. Why chlorine dioxide?

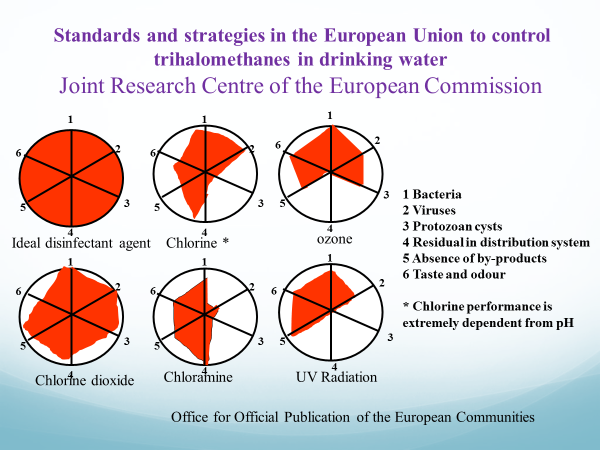

The microbiological environment where ORP (Oxidation Reduction Potential) is measured and controlled hugely influences the metabolism of micro-organisms and their ability to survive and multiply. Chlorine dioxide (ClO2) disinfects by oxidation, and NOT by chlorination, and it is very easy to control the ORP range, alternatively the level of ClO2 in the water. It is a highly selective oxidant due to its unique electron transfer ability, 5 compared to the 2 of chlorine, which leaves chlorine dioxide as a volatile energetic free radical in solutions. It is 10 times more soluble than chlorine gas, does not hydrolyze and stays in solution as a gas until consumed or removed. Finally, compared to chlorine, no THM (Trihalomethanes) byproducts are formed.

The above publication indicates chlorine dioxide as the near perfect choice of disinfection in achieving the six criteria set as benchmark.

2. What are the Advantages of Chlorine Dioxide?

- More effective than chlorine for the inactivation of viruses, Cryptosporidium and Giardia.

- It oxidizes iron, manganese and sulphides very quickly and easily.

- Does not react with ammonia nitrogen.

- Enhances clarification process, affecting the zeta potential of particles.

- TOC reduction of up to 58 %, prior dosing to the clarification process.

- Taste and odour removal, eliminating the use of powder-activated carbon.

- It has a 2.6 times higher oxidizing power than chlorine, so you can dose less.

- Chlorine dioxide does not hydrolyze and is effective over a pH 4-10 range.

- Easy to measure free residual with standard equipment.

- Capital cost significantly lower than that of a chlorine installation.

- Barriers of entry much lower due to no legislation like that of chlorine.

- Chlorine dioxide is registered with EPA (Registration No.74986-1)

- SANS 52671:2007 – Chlorine Dioxide intended for Human consumption

3. Now, what are the Disadvantages of Chlorine Dioxide?

Like any other oxidizing biocide there are negative aspects to it. However, how you minimize the effect is what matters. The BIG question to ask is “compared to what?”

- Chlorine Dioxide is manufactured on site. This eliminates a huge portion of transport as compared to other product use and may not be a negative.

- The byproducts are chlorite and chlorate. These are mitigated by the maximum dosage of 1.4 ppm in the final disinfection process to achieve the maximum limit of 0.8 ppm chlorite and 0.8 ppm chlorate. Compare this to the DBP’s of chlorine where there are 9 known listed contaminants, the biggest being THM.

- Perceived difficult chemistry. However, once it is setup and calibrated, there is no difference to any other chemical process.

- The procedure to measure chlorite and chlorate isn’t easy, but with available equipment, this is eliminated by maintaining dosage levels at less than 1.5 ppm.

- Sodium Chlorite is subject to exchange rate fluctuations, but so are most other water treatment commodities.

- Chlorine dioxide solutions of low concentration decompose under direct sunlight, so the systems are normally direct inline dosing of concentrate.

4. Why does Chlorine Dioxide work better than my Chlorine/Bromine?

Chlorine dioxide penetrates biofilm and kills it from the inside. Chlorine on the other hand “burns” it from the outside and eventually gets depleted, making it inferior… Biofilm is then removed from the surface it attaches to and gets into reject streams. The secondary effect of chlorite formed from chlorine dioxide is that it acts as a bacteriostat and retards bacterial and micro growth.

5. Why Nanotech?

Nanotech designs and manufactures ultrapure water systems such as Reverse Osmosis Systems, Electro Deionization and vapor compression distillation, where contamination is measured at part per billion levels. It is therefore only natural to design complex disinfection systems with absolute control and precision. We are not an equipment supplier of pumps and vessels. We are delivering a complete integrated system, guaranteed to exceed expectation. It is a true masterpiece of technology.

6. Which generation type or technology to select?

This is where your objectives determine the methodology of manufacturing chlorine dioxide. The mixing of powder products, 2 or 3 precursor, or chlorine gas systems can all produce Cl02. A few variables affect the choice, e.g. remote locations, level of automation required, capacities, operator skill, skilled maintenance crews, or the complexity of operation, to mention just a few. Nanotech will take all factors into consideration and give the best advice.

7. Why the technology from Nanotech?

We have designed and installed all technologies for years, including the reduction of chlorate to manufacture chlorine dioxide and chlorine gas. Each technology has its own advantages and disadvantages. For us it is the understanding of the manufacturing process of chlorine dioxide, the chemistry and the exact benefit derived for our customers. Each industry has its own expectation and benefit of the value chlorine dioxide offers, so we have taken all the lessons learned over the years and designed our systems to cater for these demanding requirements. We have designed a range of systems uniquely different from the industry norm, including complex chemistries based on ion exchange and catalysis.

8. Why is chlorine dioxide perceived to be more expensive?

Sodium hypochlorite is only 12-15% as active as “chlorine”. This hypo contains significant amounts of sodium salts and hydroxides, which adds other ionic components to the process of disinfection. If you divide the cost per kg by the concentration, immediately the cost per 100% active concentration goes up 8-times. When it hydrolyses to the active oxidation component, it doubles in cost again. Now add the exact process pH required for an efficient product, and if this does not happen, double it again. Add to this the CT values in comparison to chlorine dioxide. Is this then really such a cheap alternative to chlorine dioxide?

9. What is the life expectancy of the Nanotech generators?

We have designed these systems to last the lifetime of components and consumables, if properly maintained to schedules recommended by Nanotech. We extend our guarantees with SLA’s to keep systems running long after the due date.

10. How do I determine how much chlorine dioxide to use in my process?

This is always done with a demand study to determine exactly what the demand is for the process to overcome this “demand” and be left with a residual of typically 0.2 to 0.4 ppm of chlorine dioxide. From this demand the equipment is sized correctly to provide adequate supply of chlorine dioxide even at peak periods. Nanotech determines this demand on site over a period to compensate for seasonal or process fluctuations.

11. What are the real differences between chlorine and chlorine dioxide in a summary?

From the table above it is clear that Chlorine Dioxide is the obvious choice!

12. What maintenance is required on the Nanotech generators?

Nanotech schedules monthly and quarterly maintenance sessions to check operational availability of the system and its components.

13. How do I control chlorine dioxide dosage in my process, when is it too much or too little?

We strongly believe in measuring and controlling the variable demand in systems using ORP or residual free chlorine dioxide levels. This will keep control of the microbiological environments. Residual levels in the range of 0.2 – 0.4 ppm are typical with ORP values ranging between 750 to 780 millivolts.

14. Is Chlorine Dioxide corrosive and will it damage my equipment?

In most applications we use low dosages of chlorine dioxide, typically 1.5 ppm in potable systems and 5 ppm in wastewater. Chlorine dioxide is less corrosive than other oxidants and so is generally not a concern when it comes to corrosion.

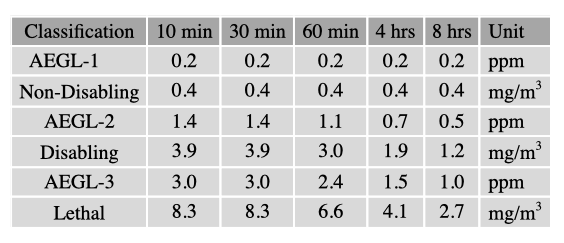

15. What is the AEGL? (Acute exposure guideline levels)

Below the data tabled for guidance should chlorine dioxide be used in confined spaces.

Based on the above questions and answers:

If you have not yet asked the question of safety, our generators are manufactured to operate in under-water conditions within solubility levels and to a maximum level of 3000 ppm. Alternatively, we produce under vacuum.

If you need a safe and reliable state-of-the-art chlorine dioxide generator to perform as per original design to deliver under any condition, our generators are the preferred choice. We guarantee the process and outcome long after you have taken ownership of the equipment.

The underwater reactors are a proudly South African development and patent pending.

Guarantee

Install one of our systems and we will maintain the system, supply the modified precursors and continuously do the checks and calibrations as required, delivering optimum performance of the system.

All components are locally available, and we keep the critical spares in stock.

Just to put you further at ease, we will know beforehand exactly what will be required for your process determined by demand tests, so there are no surprises afterwards or misunderstanding of dosage requirements.

Now it is over to YOU!

The next step is to get into contact with us and/or stay connected. Your contact person will be Jakes Jacobs and can be contacted on 083 570 8267, or email at jakes@https://nanotechsa.co.za/wp-content/uploads/2024/05/chlorine-dioxide-product-portfolio.webptechsa.co.za

LAST, but not least!

It is a known phenomenon in South Africa that skilled professionals in chlorine dioxide are a scarce and sought-after breed and therefore, a very scarce “resource” when it comes to time and cost. We therefore allocate resources to a first-come- first-served basis, especially with paying customers nowadays. We allocate project managers to manage the projects from trial to full implementation and organize the maintenance long after handover. Our clients deserve good service and support in this high-tech environment. So, call us and we will get your project seamlessly implemented and give you the peace of mind you deserve. In choosing us, you will have made the RIGHT, but INFORMED AND EDUCATED CHOICE!

By the way, have we mentioned that Nanotech is ISO 9001:2008 COMPLIANT!? This represents quality at its highest level. Safety and quality in our systems goes hand in hand to give you the peace of mind you deserve. Now in 2020, all systems are re-evaluated to get the 2015 certification. In the meantime, we are compliant to our internal quality management system.